- HOME

- Deburring Machine Solutions

- Metal Fabrication Service

- PRODUCTS

- Dry Metal Deburring Machine

- Dry or Wet Metal Finishing Machine

- Sheet Metal Leveling Machine

- Sheet Metal Embossing Machine

- Sheet Metal Laminating Machine

- Tube Polishing Machine

- Pipe Profile Bending Machine

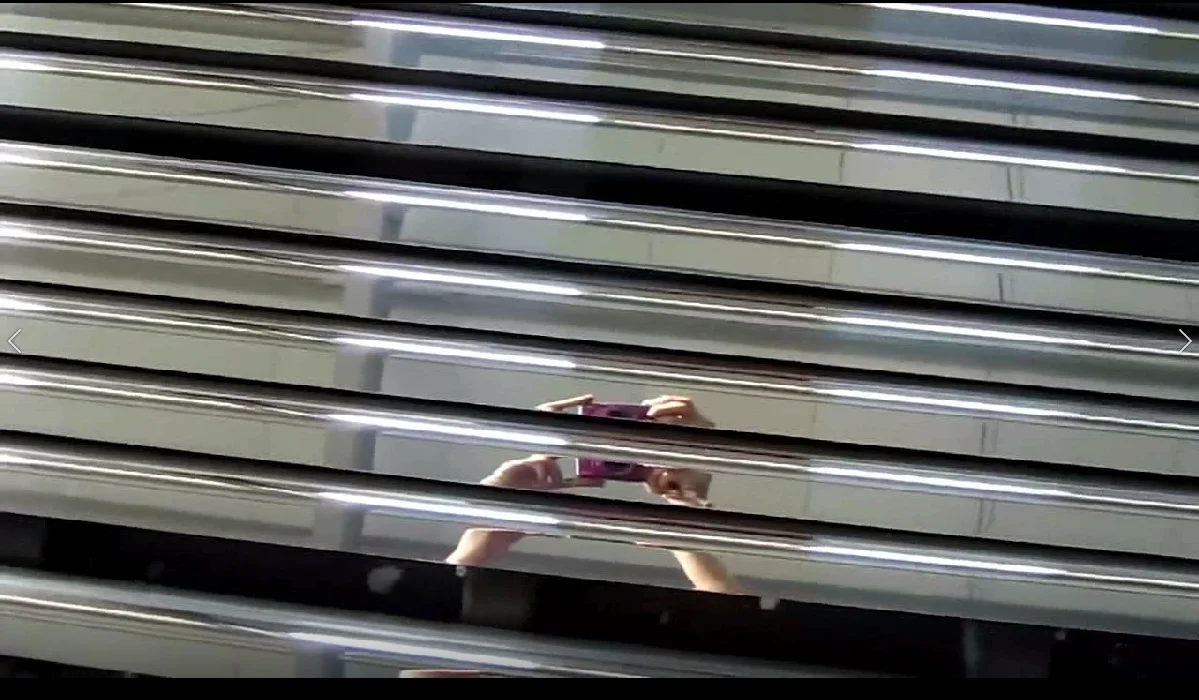

- Sheet Metal Polishing Machine

- Flat Metal Polishing Machine

- Robotic cell

- Wheel polishing machine

- Tank Dish End Polishing Machine

- Knife belt grinding machine

- Cookware polishing machine

- Laser Slat Cleaner

- Metal grinding and polishing abrasives

- Metal Band Saw Machine

- NEWS

- ABOUT US

- CONTACTS US

- HOME

- Deburring Machine Solutions

- Metal Fabrication Service

- PRODUCTS

- Dry Metal Deburring Machine

- Dry or Wet Metal Finishing Machine

- Sheet Metal Leveling Machine

- Sheet Metal Embossing Machine

- Sheet Metal Laminating Machine

- Tube Polishing Machine

- Pipe Profile Bending Machine

- Sheet Metal Polishing Machine

- Flat Metal Polishing Machine

- Robotic cell

- Wheel polishing machine

- Tank Dish End Polishing Machine

- Knife belt grinding machine

- Cookware polishing machine

- Laser Slat Cleaner

- Metal grinding and polishing abrasives

- Metal Band Saw Machine

- NEWS

- ABOUT US

- CONTACTS US